Tracing Sweetness to Its Roots - Cherry Procurement from CETARA-Certified Farmers in Himachal

At Gram Disha Trust, we believe that every piece of fruit has a story — not just of where it comes from, but of the people, practices, and purpose behind it. Our recent cherry procurement journey from the scenic slopes of Village Nankhari, Tehsil Narkanda, District Shimla is a testament to this belief, and an example of how technology, transparency, and trust can redefine agricultural value chains. The social enterprise JaivikHaat, based in Delhi, decided to create a market linkage opportunity and thereby a suitable participatory case study for Food Systems Transformation. Within the ACROPICS project, one of the leverage points is to develop market linkage mechanisms to incentivise Agroecological transformations.

The marketing partners who collaborated with JaivikHaat were – Bay Organics (Powai Based) in Mumbai and Magasool in Bangalore.

The Search for the Right Farmer Begins

Our journey started on 25th April 2025, not in a marketplace or a cold store, but on the CETARA-NF platform — a digital portal dedicated to natural farming in Himachal Pradesh. The platform allows users to search for farmers by crop, region, certification, and more. The platform was used by our Social Enteprise JaivikHaat based in Delhi to collaborate with suitable farmers who grow Cherry in the state and are at least 2/3 star farmers under the PK3Y Natural Farming Program of the Government of Himachal Pradesh.

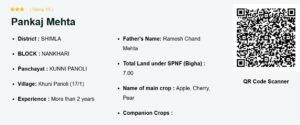

After exploring and evaluating multiple profiles, we found a perfect match on 27th April, Mr. Pankaj Mehta, a 3-star CETARA-certified natural cherry farmer, stood out as the ideal partner. His farm practices, produce quality, and traceability credentials aligned with our procurement and value chain objectives.

Collaborative Conversations Across Cities

Gram Disha Trust connected the Extention Department through the State Project Implementing Unit (SPIU) team and connected with the Farmer. A conference call on 28th April brought together stakeholders from Delhi, Bangalore, and the Himachal hills to discuss varieties, pricing, availability, and delivery timelines. The conversation wasn’t just about cherries it was about creating a transparent, mutually beneficial supply chain.

Building a Story on Every Box

To bring the farmer’s story closer to consumers, we designed an innovative label for the cherry boxes. Each label includes a QR code which directly leads you to the –

- Farmer and farm details.

- Basic produce details

By simply scanning the QR code, consumers can access real-time information about the farm and farmer, creating a direct link between farm and fork. It’s not just transparency — it’s connection. The QR Code directs consumer to the Government Evaluated CETARA-NF profile of Farmer Mr Pankaj Mehta. As the boxes are labeled to allow consumers to directly know about the farmer thus establishing Traceability from the consumer to the farmers.

Harvest, Delivery, and Distribution

The first lot of cherries left Mehta Farms on 7th May and reached Delhi, early on 8th May. From there, the produce was distributed to JHPL’s Delhi outlet and also dispatched to Bangalore amd Mumbai via Train. The procurement continued through May, with the final delivery on 3rd June, completing a total procurement of 266 kilograms of premium-quality cherries. The cultivars included –

- Durone Nero

- Merchant

- Tartarian or Black

- Sunburst

Transparent Value Chain – Farmer First

True to Gram Disha Trust’s principles, the value chain was structured to ensure upto 60% of the final consumer rupee reaches the farmer. This approach not only ensures fair compensation but also builds trust and equity into the supply system. This Innovative participatory market-led price discovery mechanism is offered to those farmers who choose to partner with JaivikHaat to share profits as well as losses. This way the final price realised by the farmers is ‘True’ to its actual realisation based on real market returns. Which is why we call this ‘True Price Accounting’ method.

Unlike conventional models, the farmer chose to receive payment after each delivery, rather than a pre-fixed price. This flexibility helped in maintaining mutual accountability and adapting to changing market conditions.

On-Ground Engagement

A key milestone of the journey was a field visit to Mehta Farms on 9th May. The visit allowed the team to:

- Observe natural farming practices in action

- Discuss challenges and improvements

- Finalize pricing based on observed quality and on-site factors

It wasn’t just a procurement visit — it was an opportunity to deepen relationships, build context, and strengthen the farmer’s voice in the value chain.

Transit Challenges and Losses at the Mumbai Outlet

While the procurement and dispatch from Himachal were executed smoothly, the journey to Mumbai brought unexpected challenges. Due to the long travel distance, changes in climate during transit, and especially exposure to rain, a portion of the cherry consignment suffered spoilage upon arrival.

Cherries, being highly perishable and sensitive to temperature fluctuations, didn’t hold up well in the changing weather conditions during the journey. This resulted in notable losses at the Bangalore and Mumbai outlets, impacting both the quantity available for sale and the potential income from this segment.

To avoid any further losses, it was decided among the marketing partners of JaivikHaat to choose to ship using Flight. This resulted in signigicant increase of the price of cherry in the other cities, however this was ameliorated by JaivikHaat by sharing partial costs with the partners, and also sourcing additional fruits from Himachal Pradesh, aggregating them and shipping them in single lots. This spread the cost and averaged it for better weight efficiency realisations. The cargo airlines offers brackets of weight and volume, therefore JaivikHaat maximised this by better sourcing and time management with its marketin partners in other cities. This brought down the wastage immediately and the marketing effort continued.

These setbacks have highlighted the need for:

- Improved cold chain logistics

- Faster transit scheduling

- Possibly pre-sorting varieties based on shelf life

Despite the losses, this experience has added important learning for future procurement planning — particularly when dealing with distant markets and highly perishable produce.

Aspects of Agroecological Production - Participatory Advisory to Producer

Gram Disha Trust and JaivikHaat form a deeper bond with the producer by offering participatory feedback, now just on market acccess, but also compliances, production practices and post harvest loss prevention.

There are three specific cases to consider here –

1. Residue Avoidance – Ensuring Chemical-Free Produce

To ensure transparency and uphold the integrity of sustainable procurement, the first batch of produce is routinely tested for chemical residues after procurement. This proactive step reassures both buyers and consumers about the authenticity and safety of naturally grown produce. During one such testing phase, traces of copper oxychloride were detected. The concerned farmer was immediately informed and guided on appropriate corrective measures and alternative practices. According to the FSSAI regulations for Organic Foods the maximum residue limit allowed for Copper Oxychloride expressed as copper is 1mg/kg. The residue which appeared in this case was marginally over this limit. This allowed the farmer to immediately check the correct dosage and application process thus ensuring immediate feedback and remidiation. The world over Copper oxychloride is also permissible in restricted use for Organic Farming, see this paper for more details.

This not only helped build awareness at the farmer level but also reinforced the importance of following natural farming protocols consistently. By identifying residues early, compromised produce is excluded from the supply chain, thereby protecting consumer trust and maintaining the organic or natural credibility of the farm.

2. CETARA-NF Star Rating Advisory – Promoting Free Natural Certification

As the farmer is a 3-star farmer, it is advised that they rely on their own inputs. Therefore, we have also recommended that the farmer undertake a reassessment of their CETARA-NF certificate to see if the use of Copper Oxychloride causes any Star Rating change for the farmer. We also supported filing feedback with the Department for the same process. This is also important since the farmer must be honest in their approach to Natural Farming. It is likely that they may still retain the 3-star since the CETARA rating is based on a range of scores rather than fixed points. As the use of Copper Oxychloride shall reduce the score of ‘-2’ points we are confident that the farmer may still retain a 3-star or in the worst case acquire a 2-star rating. We plan to continue supporting the farmer in their journey nonetheless based on complete transparency of process between producer and consumer.

Many farmers in the region already follow natural farming practices but lack formal certification, which limits their marketability. To bridge this gap, an advisory initiative was launched to introduce them to the CETARA-NF Star Rating a free-of-cost certification for natural farming. By informing farmers about its benefits and guiding them through the process, the initiative aims to enhance their market access, build consumer confidence, and improve traceability, ultimately leading to better pricing and long-term sustainability.

3. Wastage Avoidance – Strategic Packaging and Transport Solutions

A significant amount of post-harvest loss was observed due to temperature fluctuations, long-distance logistics, and handling during multi-modal transportation from Narkanda to Bangalore involving trucks, trains, and smaller vehicles. To mitigate these losses, a revised packaging strategy was implemented. This included using double-layered cartons, adding separators between produce layers to avoid bruising, and improving ventilation within boxes to maintain quality. It was also discussed that the farmer may consider to reduce the per punnet grammage to 700gms to ensure that the cherries do not spoil due to top pressure. Usually other farmers prepare cardboard boxes layered with two or three layers of cherry. However, in this case there is a chance that the grade of cherry in the lower layers is of poor quality. The punnet allows for the entire lot to be visible to the consumers. The trade-off is that the punnet is currently made of plastic and we look forward to a time when we can replace this solution with other more nature friendly ones. These solutions effectively minimized damage from mishandling, condensation, and spoilage, thereby improving shelf life and reducing wastage during transit.

What We Learned And What We’re Still Exploring

This cherry procurement wasn’t just about fruit it was a pilot in value chain discovery, real-time traceability, and farmer-led pricing flexibility.

Pingback: Residual Effect – 3 star Rated Farms – GRAM DISHA TRUST